+86-576-83500077

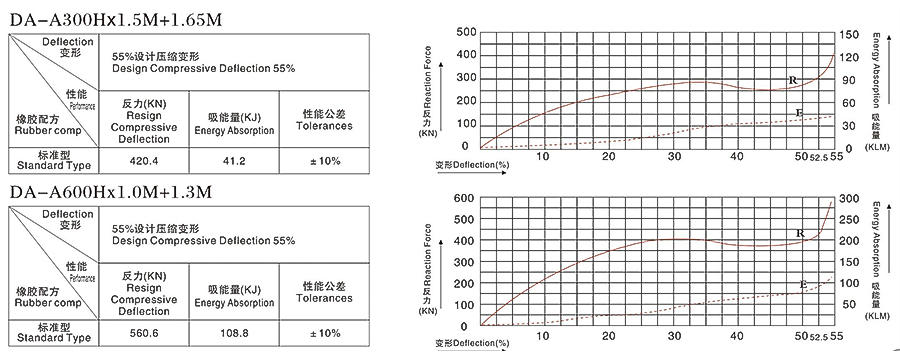

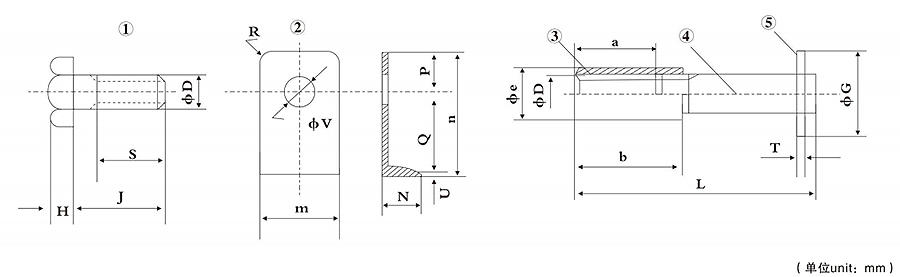

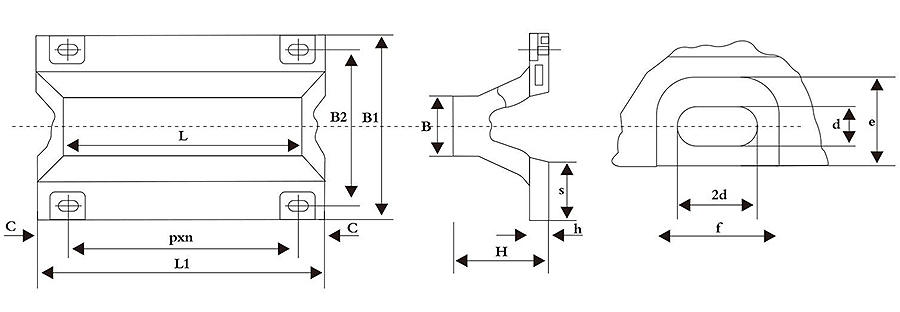

| Type | Specification | |||||||||||||

| H | L | L1 | B | B1 | B2 | C | d | e | f | h | Q | S | N | |

| DA-A200Hx1.0M+1.1M | 200 | 1000 | 1100 | 145 | 400 | 320 | 120 | 29 | 75 | 105 | 30 | 860 | 128 | 2 |

| DA-A200Hx1.5M+1.6M | 200 | 1500 | 1600 | 145 | 400 | 320 | 120 | 29 | 75 | 105 | 30 | 680 | 128 | 3 |

| DA-A200Hx2.0M+2.1M | 200 | 2000 | 2100 | 145 | 400 | 320 | 120 | 29 | 75 | 105 | 30 | 620 | 128 | 4 |

| DA-A200Hx2 .5M+2.6M | 200 | 2500 | 2600 | 145 | 400 | 320 | 122.5 | 29 | 75 | 105 | 30 | 785 | 128 | 4 |

| DA-A200Hx3.0M+3.1M | 200 | 3000 | 3100 | 145 | 400 | 320 | 120 | 29 | 75 | 105 | 30 | 715 | 128 | 5 |

| DA-A200Hx3.5M+3.6M | 200 | 3500 | 3600 | 145 | 400 | 320 | 120 | 29 | 75 | 105 | 30 | 672 | 128 | 6 |

| DA-A250Hx1.0M+1.125M | 250 | 1000 | 1125 | 175 | 500 | 410 | 130 | 32 | 90 | 125 | 33 | 865 | 160 | 2 |

| DA-A250Hx1.5M+1625M | 250 | 1500 | 1625 | 175 | 500 | 410 | 132.5 | 32 | 90 | 125 | 33 | 680 | 160 | 3 |

| DA-A250Hx2.0M+2.125M | 250 | 2000 | 2125 | 175 | 500 | 400 | 132.5 | 32 | 90 | 125 | 33 | 620 | 160 | 4 |

| DA-A250Hx2.5M+2.625M | 250 | 2500 | 2625 | 175 | 500 | 400 | 127.5 | 32 | 90 | 125 | 33 | 790 | 160 | 4 |

| DA-A250Hx3.0M+3.125M | 250 | 3000 | 3125 | 175 | 500 | 400 | 132.5 | 32 | 90 | 125 | 33 | 715 | 160 | 5 |

| DA-A250Hx3.5M+3.625M | 250 | 3500 | 3625 | 175 | 500 | 400 | 130 | 32 | 90 | 125 | 33 | 673 | 160 | 6 |

| DA-A300Hx1.0M+1.15M | 300 | 1000 | 1150 | 225 | 600 | 490 | 140 | 35 | 105 | 140 | 33 | 870 | 195 | 2 |

| DA-A300Hx1.5M+1.65M | 300 | 1500 | 1650 | 225 | 600 | 490 | 140 | 35 | 105 | 140 | 33 | 685 | 195 | 3 |

| DA-A300Hx2.0M+2.15M | 300 | 2000 | 2150 | 225 | 600 | 490 | 137.5 | 35 | 105 | 140 | 33 | 625 | 195 | 4 |

| DA-A300Hx2.5M+2.65M | 300 | 2500 | 2650 | 225 | 600 | 490 | 140 | 35 | 105 | 140 | 33 | 790 | 195 | 4 |

| DA-A300Hx3.0M+3.15M | 300 | 3000 | 3150 | 225 | 600 | 490 | 145 | 35 | 105 | 140 | 33 | 715 | 195 | 5 |

| DA-A300Hx3.5M+3.65M | 300 | 3500 | 3650 | 225 | 600 | 490 | 140 | 35 | 105 | 140 | 33 | 674 | 195 | 6 |

| DA-A400Hx1.0M+1.2M | 400 | 1000 | 1200 | 300 | 800 | 670 | 0.15 | 41 | 120 | 165 | 40 | 900 | 260 | 2 |

| DA-A400Hx15M+1.7M | 400 | 1500 | 1700 | 300 | 800 | 670 | 150 | 41 | 120 | 165 | 40 | 700 | 260 | 3 |

| DA-A400Hx2.0M+2.2M | 400 | 2000 | 2200 | 300 | 800 | 670 | 147.5 | 41 | 120 | 165 | 40 | 635 | 260 | 4 |

| DA-A400Hx2.5M+2.7M | 400 | 2500 | 2700 | 300 | 800 | 670 | 150 | 41 | 120 | 165 | 40 | 800 | 260 | 4 |

| DA-A400Hx3.0M+3.2M | 400 | 3000 | 3200 | 300 | 800 | 670 | 0.15 | 41 | 120 | 165 | 40 | 725 | 260 | 5 |

| DA-A400Hx3.5M+3.7M | 400 | 3500 | 3700 | 300 | 800 | 670 | 150 | 41 | 120 | 165 | 40 | 680 | 260 | 6 |

| DA-A500Hx1.0M+1.25M | 500 | 1000 | 1250 | 375 | 1000 | 840 | 160 | 47 | 140 | 180 | 45 | 930 | 325 | 2 |

| DA-A500Hx1.5M+1.75M | 500 | 1500 | 1750 | 375 | 1000 | 840 | 160 | 47 | 140 | 180 | 45 | 715 | 325 | 3 |

| DA-A500Hx2.0M+2.25M | 500 | 2000 | 2250 | 375 | 1000 | 840 | 157.5 | 47 | 140 | 180 | 45 | 645 | 325 | 4 |

| DA-A500Hx2.5M+2.75M | 500 | 2500 | 2750 | 375 | 1000 | 840 | 160 | 47 | 140 | 180 | 45 | 810 | 325 | 4 |

| DA-A500Hx3.0M+3.25M | 500 | 3000 | 3250 | 375 | 1000 | 840 | 0.165 | 47 | 140 | 180 | 45 | 730 | 325 | 5 |

| DA-A500Hx3.5M+3.75M | 500 | 3500 | 3750 | 375 | 1000 | 840 | 160 | 47 | 140 | 180 | 45 | 686 | 325 | 6 |

| DA-A500Hx4.0M+4.25M | 500 | 4000 | 4250 | 375 | 1000 | 840 | 160 | 47 | 140 | 180 | 54 | 786 | 325 | 6 |

| DA-A600Hx1.0M+1.3M | 600 | 1000 | 1300 | 450 | 1200 | 1010 | 170 | 50 | 160 | 195 | 54 | 960 | 390 | 2 |

| DA-A600Hx1.5M+1.8M | 600 | 1500 | 1800 | 450 | 1200 | 1010 | 170 | 50 | 160 | 195 | 54 | 730 | 390 | 3 |

| DA-A600Hx2.0M+2.3M | 600 | 2000 | 2300 | 450 | 1200 | 1010 | 167.5 | 50 | 160 | 195 | 54 | 655 | 390 | 4 |

| DA-A600Hx2.5M+2.8M | 600 | 2500 | 2800 | 450 | 1200 | 1010 | 170 | 50 | 160 | 195 | 54 | 820 | 390 | 4 |

| DA-A600Hx3.0M+3.3M | 600 | 3000 | 3300 | 450 | 1200 | 1010 | 170 | 50 | 160 | 195 | 54 | 740 | 390 | 5 |

| DA-A600Hx3.5M+3.8M | 600 | 3500 | 3800 | 450 | 1200 | 1010 | 170 | 50 | 160 | 195 | 54 | 692 | 390 | 6 |

| DA-A800Hx1.0M+1.4M | 800 | 1000 | 1400 | 600 | 1600 | 1340 | 180 | 68 | 260 | 270 | 72 | 1040 | 520 | 2 |

| DA-A800Hx1.5M+1.9M | 800 | 1500 | 1900 | 600 | 1600 | 1340 | 180 | 68 | 260 | 270 | 72 | 770 | 520 | 3 |

| DA-A1000Hx1.0M+1.5M | 1000 | 1000 | 1500 | 750 | 2000 | 1680 | 200 | 68 | 300 | 290 | 90 | 1100 | 650 | 2 |

| DA-A1000Hx1.5M+2.0M | 1000 | 1500 | 2000 | 750 | 2000 | 1680 | 200 | 68 | 300 | 290 | 90 | 800 | 650 | 3 |

English

English Español

Español 中文简体

中文简体