Fender installation method

There are three ways to install the fixed CRF fenders, one is to have steel plates wrapped around the piers, and the fenders are installed on the outside of the steel plates; - one is to use the pull bolt holes, the piers are wrapped with steel strips, and the fenders are fixed on the steel strips, provided that The piers should reserve bolt holes for tension; - The first is the way of pre-embedded steel plates.

Bridge pier outsourcing steel plate - first roughen the outside of the bridge pier that needs to be outsourced steel plate, first splicing and fixing the steel plate by planting glue, compacting, so that the steel plate and the bridge pier are in close contact; weld the splicing seam between the steel plate into a whole; Anti-corrosion treatment is carried out after welding.

This installation method is suitable for completed bridges or it is strictly required that no

How to operate bridges, such as railway bridges. The bottom of the outsourcing steel plate should reach the bearing platform, and the distance between the undefended parts

Bridges with long caps are uneconomical.

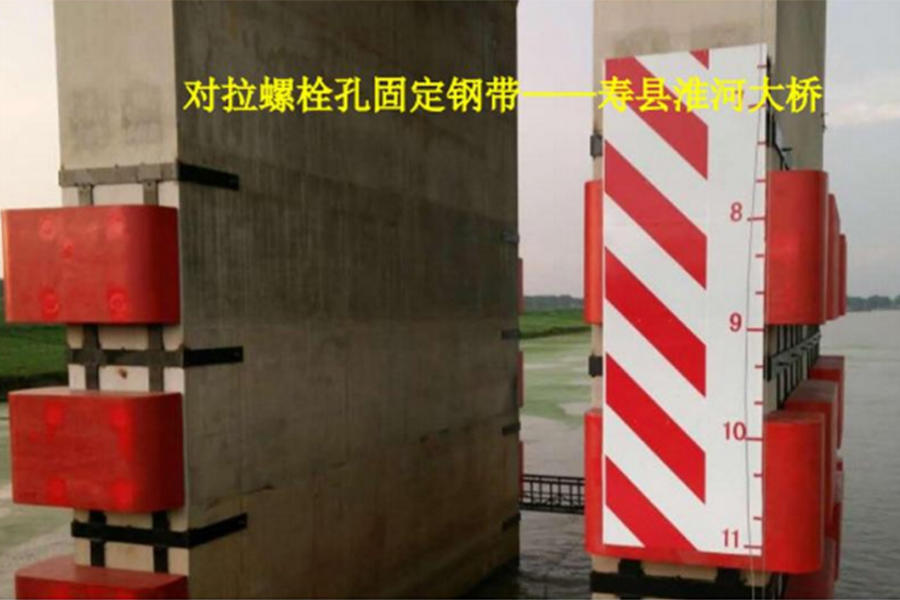

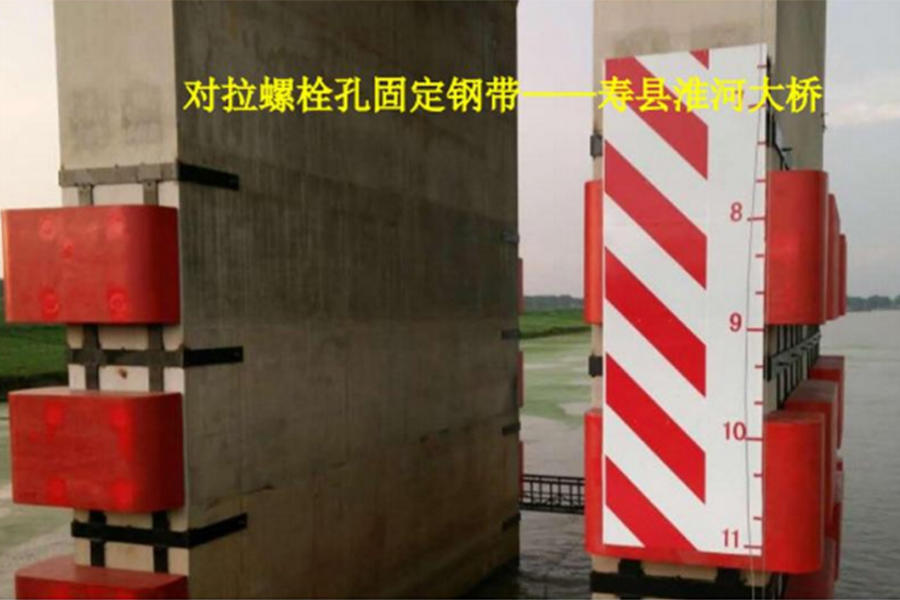

Steel plate for fixing bolt holes 1 - suitable for bridge piers with formwork opposite drawing holes after the pier construction is completed, the steel belt (steel hoop) is fixed by the fastening screw, and the fastening screw uses the original pier formwork opposite drawing hole , Avoid drilling holes in other parts of the pier body.

This installation method saves steel, but affects the beauty of the bridge body, the steel belt is exposed, and the later maintenance is also troublesome.

Pre-embedded steel plate—the inner surface of the pre-embedded steel plate is inserted into the steel cage of the pier by planting bars, and it is made into a whole by pouring concrete. The outer surface of the steel plate and the surface of the pier are on the same plane, without forming protrusions and affecting the pier body beautiful. The later maintenance and replacement of the fenders are only carried out on the surface of the steel plate and will not affect the pier structure.

English

English Español

Español 中文简体

中文简体