The SUC Super Drum Type Rubber Fender is a commonly used rubber fender in the marine industry. The processing method for manufacturing the SUC Super Drum Type Rubber Fender involves the following steps:

Mixing the rubber compound: The first step involves mixing the rubber compound, which consists of natural or synthetic rubber, carbon black, and other additives. The rubber compound is mixed in a kneading machine until it is uniform.

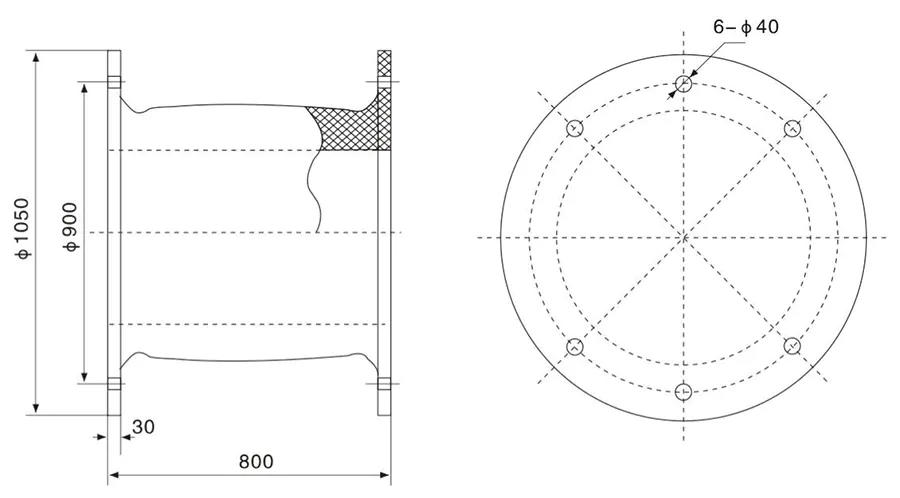

Shaping the rubber: The rubber compound is then shaped into a cylindrical drum using a hydraulic press or extrusion machine. The diameter and length of the drum depend on the size of the fender required.

Curing the rubber: The shaped rubber is then cured by heating it in an autoclave at high pressure and temperature for a specific period. This process ensures that the rubber is vulcanized and has the required physical properties.

Reinforcing the fender: To provide additional strength and support to the fender, steel bars or chains are embedded inside the rubber during the curing process.

Finishing the fender: After curing, the fender is trimmed, painted, and marked with the required information, such as size, type, and manufacturer.

Testing the fender: Before the fender is shipped, it undergoes various tests to ensure that it meets the required standards and specifications. These tests include compression, elongation, and impact tests, among others.

The processing method for manufacturing the SUC Super Drum Type Rubber Fender is designed to ensure that the fender has the required strength, durability, and energy absorption capacity to protect vessels and docks during berthing and mooring operations.

The SUC Super Drum Type Rubber Fender is designed to absorb the kinetic energy of a vessel during berthing and mooring operations. The principle behind the SUC Super Drum Type Rubber Fender is based on the following:

1. Energy absorption: The SUC Super Drum Type Rubber Fender is made of a high-quality rubber compound that is capable of absorbing large amounts of energy. When a vessel comes into contact with the fender, the rubber compresses and deforms, absorbing the kinetic energy of the vessel and reducing the impact force.

2. Distributed load: The shape of the SUC Super Drum Type Rubber Fender is cylindrical, which allows for a distributed load during impact. The cylindrical shape spreads the load over a larger area, reducing the stress on the fender and improving its durability.

3. Reinforcement: The SUC Super Drum Type Rubber Fender is reinforced with steel bars or chains embedded inside the rubber. This reinforcement provides additional strength and support to the fender, allowing it to withstand the impact of a vessel.

4. Low reaction force: The SUC Super Drum Type Rubber Fender has a low reaction force, which is the force exerted back on the vessel during impact. The low reaction force reduces the risk of damage to the vessel and allows for safe berthing and mooring operations.

The principle of the SUC Super Drum Type Rubber Fender is to provide a reliable and effective solution for protecting vessels and docks during berthing and mooring operations. By absorbing the energy of the vessel, distributing the load, and providing a low reaction force, the SUC Super Drum Type Rubber Fender helps to prevent damage to both the vessel and the dock.

English

English Español

Español 中文简体

中文简体