+86-576-83500077

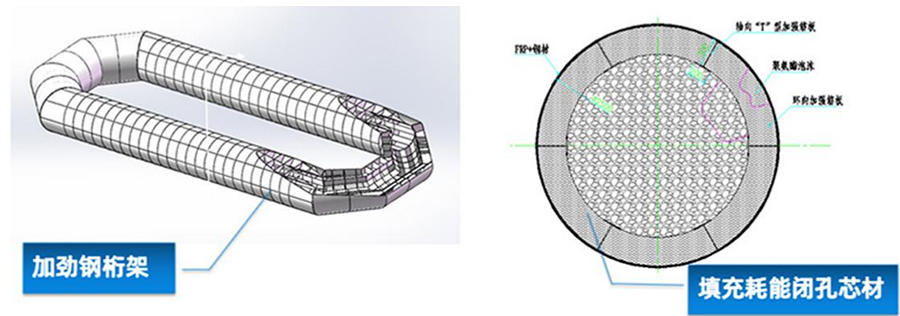

| Self-floating steel-clad composite anti-collision facilities | Anti-collision pier | |

| Working principle | The anti-collision facility system itself can withstand a large impact force. It can maximize the safety of ships and bridges. | Head-to-head, mainly through joint deformation of pile groups to buffer and dissipate energy. |

| Anti-collision performance | Combining the high energy consumption of plastic deformation of steel and the good flexibility of composite materials, the combination of deformation and energy dissipation can greatly reduce the impact force and can be used many times | Rigid anti-collision can prevent the ship from touching the pier, but the pile group cannot play the anti-collision effect after being damaged by collision. |

| Anti-collision effect | Impact force reduced to 30% 40%. | Head-to-head, the ship was seriously damaged |

| Exterior | The anti-collision facilities made of steel-clad composite materials are orange-red as a whole, have a beautiful appearance, and can play a traffic guiding role. | Fixed, unsightly, severely exposed after the water level drops |

| Construction Difficulty | The anti-collision facilities are light in weight, easy to transport and install, and have a short installation period. The anti-collision facilities are connected by bolts to form a whole. | Steel pipe piles are constructed on site by piling barge and concrete is poured inside. The construction has certain difficulties. |

| Number of collisions | When it is hit by a small and medium ship, the deformation can be recovered; when it is hit by a large ship, the composite anti-collision section is easy to replace. | From an economic point of view, small energy collisions are more reasonable. Easily damaged by large collisions |

| Impact on the hull | The overall elastic modulus is lower than that of steel, and the damage to the ship is small. | Rigid collision, the ship deformed and damaged seriously. |

| Will water enter after damage | No anti-corrosion coating, no pollution. | It will encroach on the river channel and make demolition difficult. |

| Service life | The service life is more than 30 years. | The service life is about 50 years. |

| Damage repair | When there is a small area of damage to the anti-collision facility, it can be quickly repaired by hand lay-up; when there is a large area of damage, a single segment can be replaced. | It is easy to be knocked down, the deformation accumulates, and it is difficult to repair; the damage cannot be repaired. |

| Post-maintenance | Composite materials are durable and require little maintenance. | Extremely difficult to maintain after a crash |

| Cost | About 30-50w/pier, measured in the whole life cycle, more economical. | Each three-pipe pile is about 50w-80w. |

English

English Español

Español 中文简体

中文简体