Enhancing Maritime Safety: The Role Of Ship Rubber Fenders And Pontoon Dock Fenders

In the dynamic realm of maritime operations, ensuring the safety of vessels and waterfront structures is paramount. Two crucial components contributing to this safety are ship rubber fenders and pontoon dock fenders. These innovative technologies play a pivotal role in mitigating impact forces, safeguarding ships, and preserving the integrity of docks. This article delves into the significance of ship rubber fenders and pontoon dock fenders, exploring their functions, types, and the positive impact they have on maritime safety.

Ship Rubber Fenders:

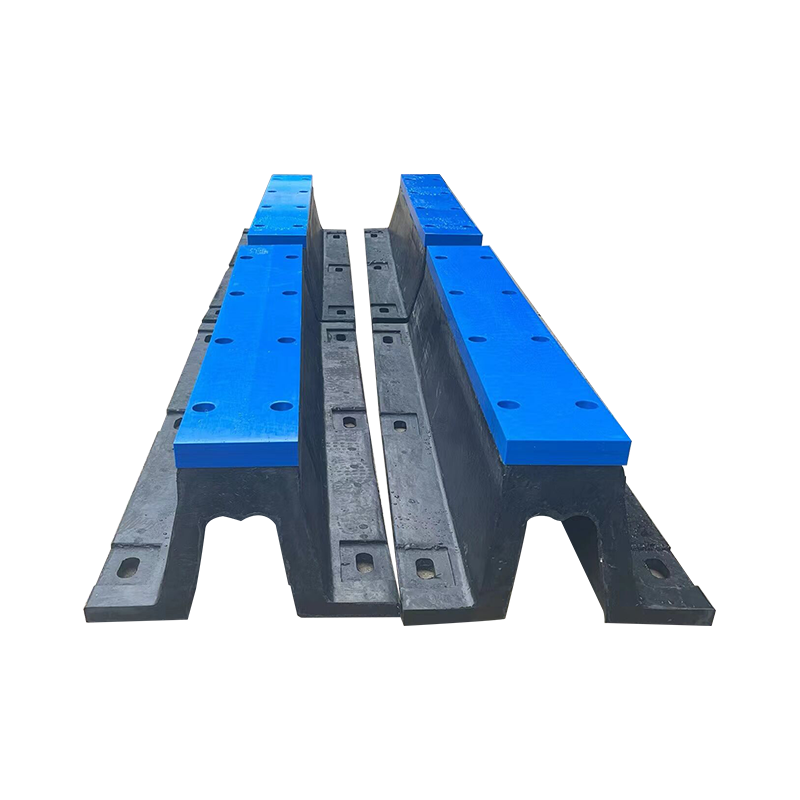

Ship rubber fenders are indispensable tools designed to absorb kinetic energy during vessel berthing and mooring. These fenders act as a protective barrier, preventing damage to both the ship and the docking infrastructure. Comprising durable rubber materials, they provide a resilient cushion against collisions, reducing the risk of structural harm. The versatility of ship rubber fenders is evident in their various types, including cylindrical, D-shaped, and cone fenders, each tailored to specific vessel requirements and docking conditions.

The benefits of ship rubber fenders extend beyond damage prevention. They facilitate smooth berthing operations, fewer downtime and optimizing port efficiency. Additionally, the enhanced safety they offer reduces maintenance costs associated with repairs to ships and port facilities.

Pontoon Dock Fenders:

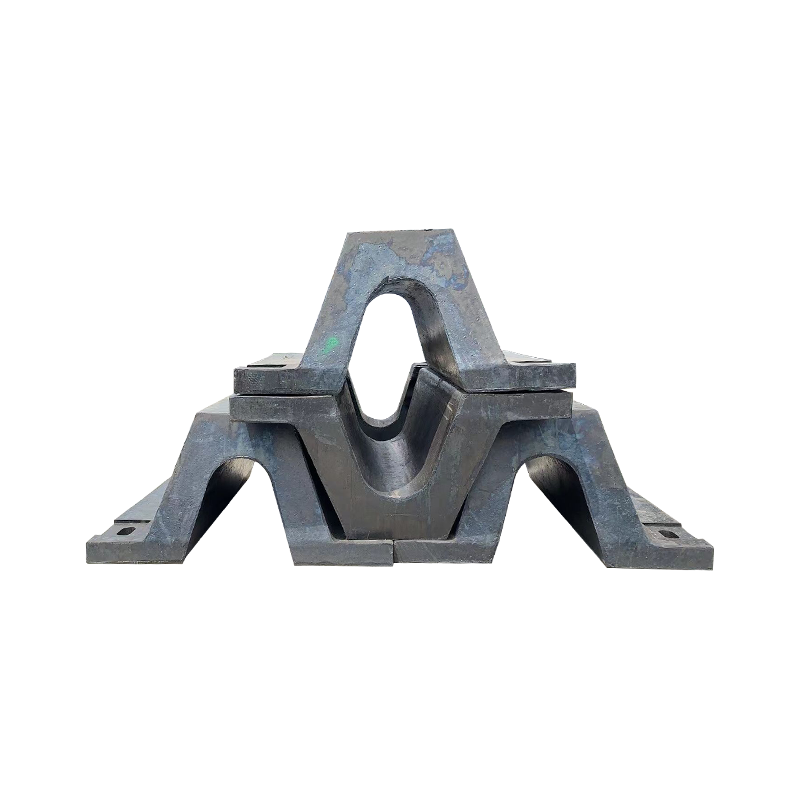

Pontoon dock fenders, another critical element in maritime safety, are designed to protect pontoons and floating docks from the forces exerted by vessels. These fenders create a buffer zone between the pontoon structure and incoming ships, absorbing energy and mitigating the risk of pontoon damage. The modular nature of pontoon dock fenders allows for customizable configurations, adapting to various dock layouts and environmental conditions.

The advantages of pontoon dock fenders extend beyond their protective function. They contribute to the longevity of waterfront infrastructure, fewer the need for frequent repairs and replacements. Furthermore, their design ensures that vessels can safely dock and undock, promoting efficient maritime operations.

Innovations and Advancements:

Recent advancements in materials and design have further improved the performance of both ship rubber fenders and pontoon dock fenders. High-performance elastomers and innovative geometric shapes enhance durability and energy absorption capabilities. Moreover, technological integrations, such as sensors and monitoring systems, provide real-time data on fender conditions, allowing for proactive maintenance and ensuring continuous safety.

In conclusion, ship rubber fenders and pontoon dock fenders play instrumental roles in enhancing maritime safety. These technologies not only protect vessels and waterfront structures but also contribute to the efficiency and sustainability of port operations. As maritime industries continue to evolve, the ongoing development of ship fender technologies will undoubtedly shape a safer and more resilient future for global shipping and docking activities.

English

English Español

Español 中文简体

中文简体