Enhancing Docking Safety: The Role Of Rubber Fender Factory In Marine Industry

Supply High Quality Sale Rubber Fender Factory Suppliers

In the vast and dynamic domain of maritime operations, safety stands as a paramount concern. Within this framework, the significance of rubber fender factory cannot be overstated. These factories play a pivotal role in enhancing docking safety, thereby ensuring smooth and secure operations in the marine industry.

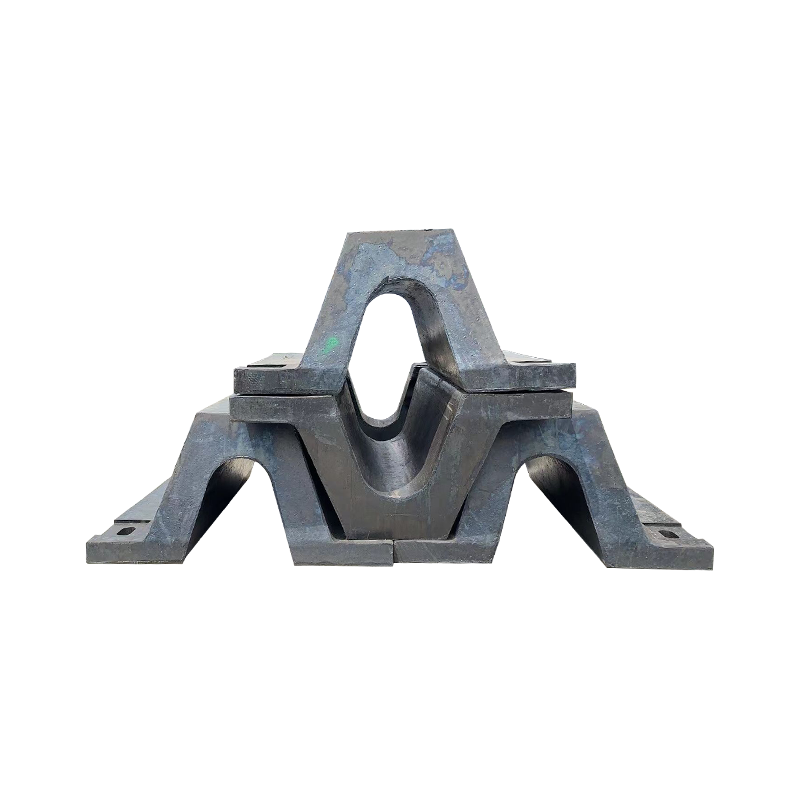

Rubber fender factory, equipped with advanced technology and expertise, serves as the backbone of marine infrastructure. The primary function of these factories revolves around the production of rubber fenders, critical components that absorb kinetic energy during vessel berthing and docking maneuvers. These fenders act as a cushion, preventing damage to both the vessel and the docking structure.

The importance of rubber fender factory lies in its ability to provide tailor-made solutions for diverse docking scenarios. Whether it's a bustling commercial port or a small marina, these factories offer a wide range of fender types and configurations to suit specific requirements. From cylindrical fenders to cone fenders, each product undergoes rigorous testing to ensure durability and reliability under varying conditions.

Moreover, rubber fender factory plays a vital role in innovation within the marine industry. Continuous research and development efforts result in the creation of advanced fender designs that offer predominant performance and longevity. By staying at the forefront of technological advancements, these factories contribute significantly to the overall safety standards of docking facilities worldwide.

Furthermore, the expertise of rubber fender factory extends beyond product manufacturing. These entities often provide consultation services to port authorities, shipyards, and maritime engineers. Through comprehensive assessments and site evaluations, they offer valuable insights into fender selection, installation, and maintenance practices. This collaborative approach ensures ideal performance and longevity of docking systems.

In addition to safety, rubber fender factory also plays a crucial role in environmental sustainability. By utilizing high-quality materials and adhering to eco-friendly manufacturing processes, these factories small their carbon footprint. This commitment to sustainability aligns with global initiatives aimed at preserving marine ecosystems and reducing maritime pollution.

The reliability and effectiveness of rubber fender factory have earned them a reputation as industry pilots. Port operators and maritime stakeholders trust these entities to deliver solutions that meet the high standards of quality and performance. The widespread adoption of rubber fender factory products underscores their indispensable role in ensuring safe and efficient docking operations.

Moreover, rubber fender factory fosters collaborations with industry partners to explore innovative technologies and methodologies. By leveraging data analytics, simulation tools, and predictive maintenance algorithms, they optimize fender design and deployment strategies. This data-driven approach not only enhances safety but also small downtime and operational costs for port operators.

Furthermore, rubber fender factory emphasizes the importance of ongoing training and education for stakeholders within the marine industry. Through workshops, seminars, and informational materials, they empower port personnel and ship crews with the knowledge and skills necessary to effectively utilize and maintain fender systems.

As global trade continues to expand, rubber fender factory remains committed to meeting the evolving needs of the maritime community. Whether it's developing custom solutions for specialized vessels or introducing sustainable materials for fender production, these factories strive to stay ahead of the curve.

Moreover, the expertise and innovation of rubber fender factories continually push the boundaries of fender design and performance. Research and development efforts focus on improving fender materials, enhancing energy absorption capabilities, and optimizing fender geometries to meet the evolving needs of the maritime industry.

English

English Español

Español 中文简体

中文简体